Associate Professor

Jointly in the Department of Metallurgical and Materials Engineering & Centre of Nanotechnology, IIT Roorkee

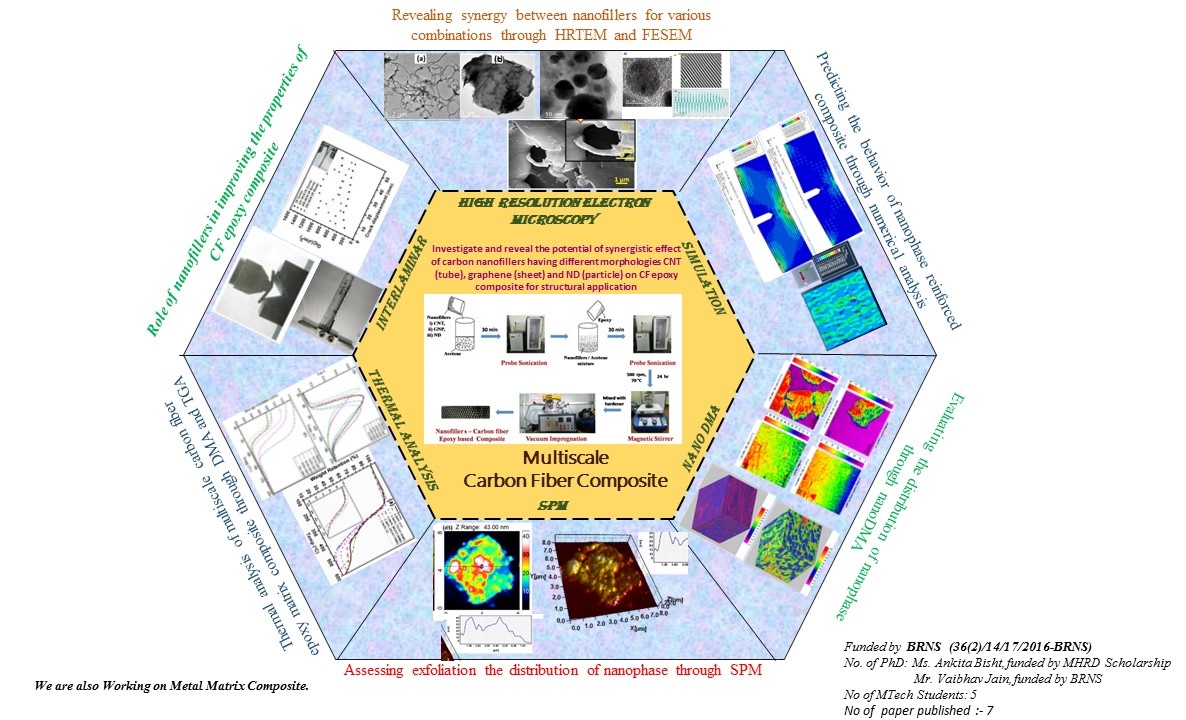

Our group is involved in developing materials systems and exploring their potential in biomedical and structural applications.

Jointly in the Department of Metallurgical and Materials Engineering & Centre of Nanotechnology, IIT Roorkee

Jointly in the Department of Metallurgical and Materials Engineering & Centre of Nanotechnology, IIT Roorkee

Florida International University, Miami, Florida

Florida International University, Miami, Florida

Ph.D. in Materials Science and Engineering

Florida International University (FIU), Miami, Florida, USA

Materials & Metallurgical Engineering

Indian Institute of Technology (IIT) Kanpur, India

Metallurgical Engineering

Bengal Engineering College, Shibpur, India

*For all publications click here

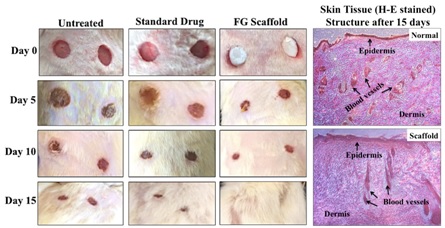

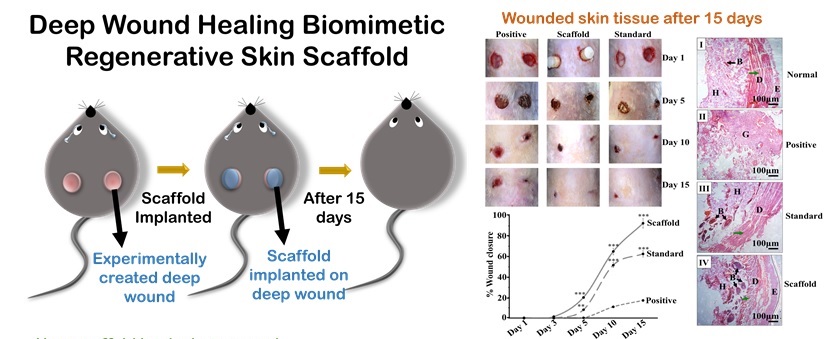

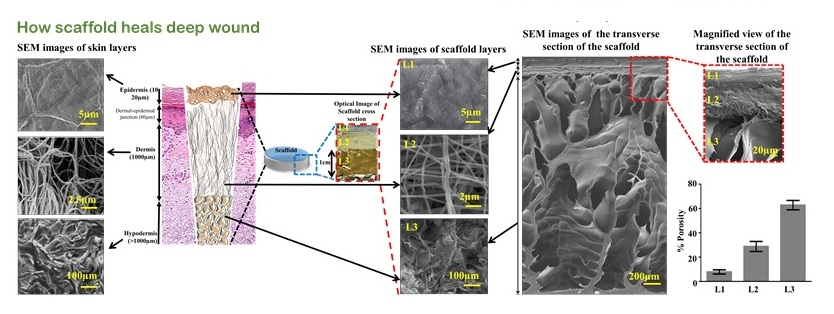

Deep Wound Healing Scaffold: We have designed a novel biomimetic fully biodegradable scaffold that can regenerate and heal full thickness wounds without any follow-up surgery for epidermal sealing with skin graft. Efficacy of the prototype scaffold in wound healing has been verified on rat wounds. The invention has been filed for patenting (Indian Patent Office - application number 201911007235). Salient features of this invention are:

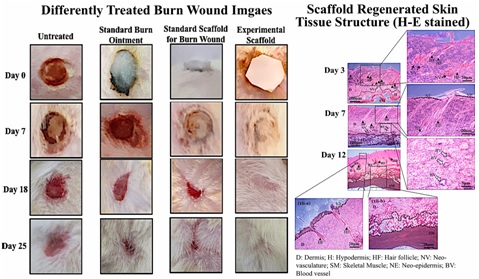

Burn Wound Healing Scaffold: Our burn wound healing scaffold has a unique design capable of supporting the three crucial stages of burn wound healing, namely, reactive, reparative and reconstructive. The design of the scaffold allows protection from bacterial infection, the sole reason behind high rate of severe burn related mortality. In addition, the scaffold provides scar free healing by reducing inflammation and efficient tissue reconstruction. Efficacy of the prototype scaffold in established in burn wound model of rat. A patent has been applied for this invention as well (Indian Patent Office - application number 201911026834). Salient features of this invention are:

Debrupa Lahiri

Associate Professor

Department of Metallurgical and Materials Engineering Indian Institute of Technology Roorkee Roorkee, Uttarakhand - 247667, India