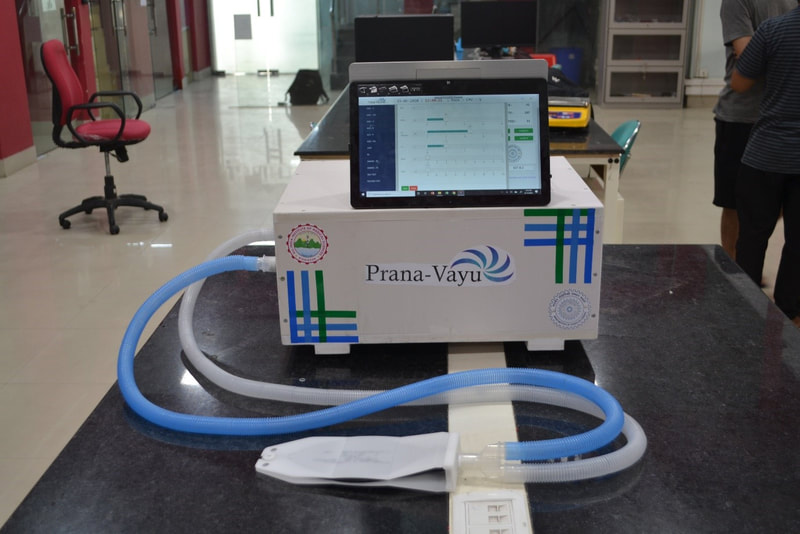

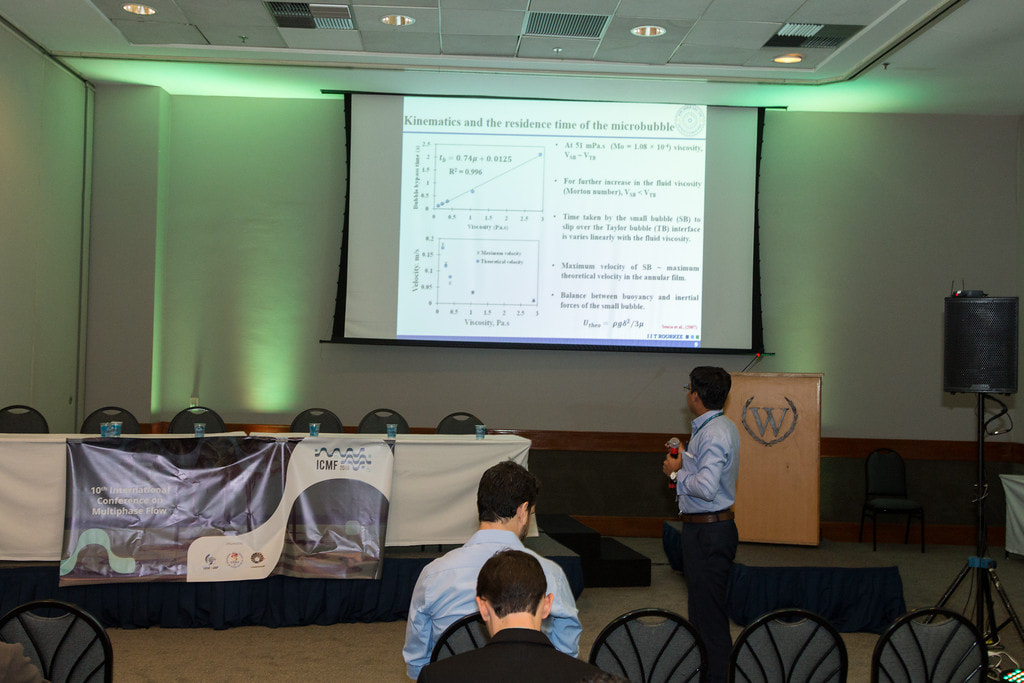

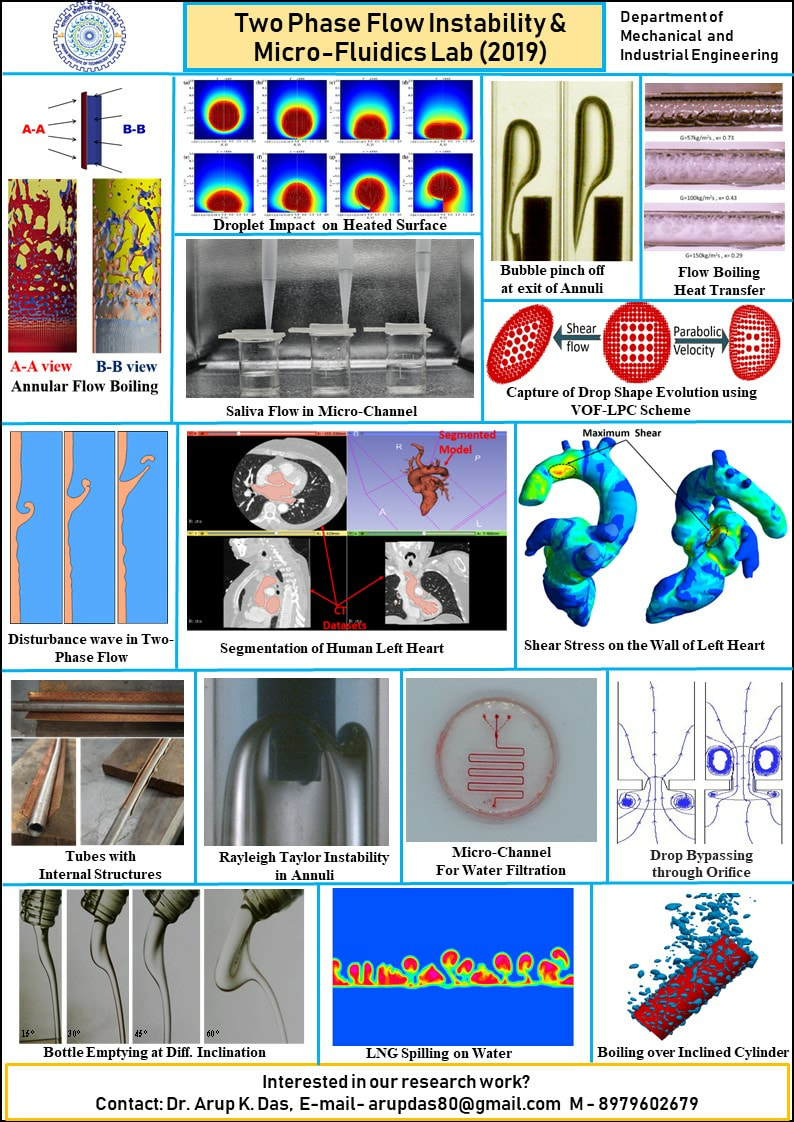

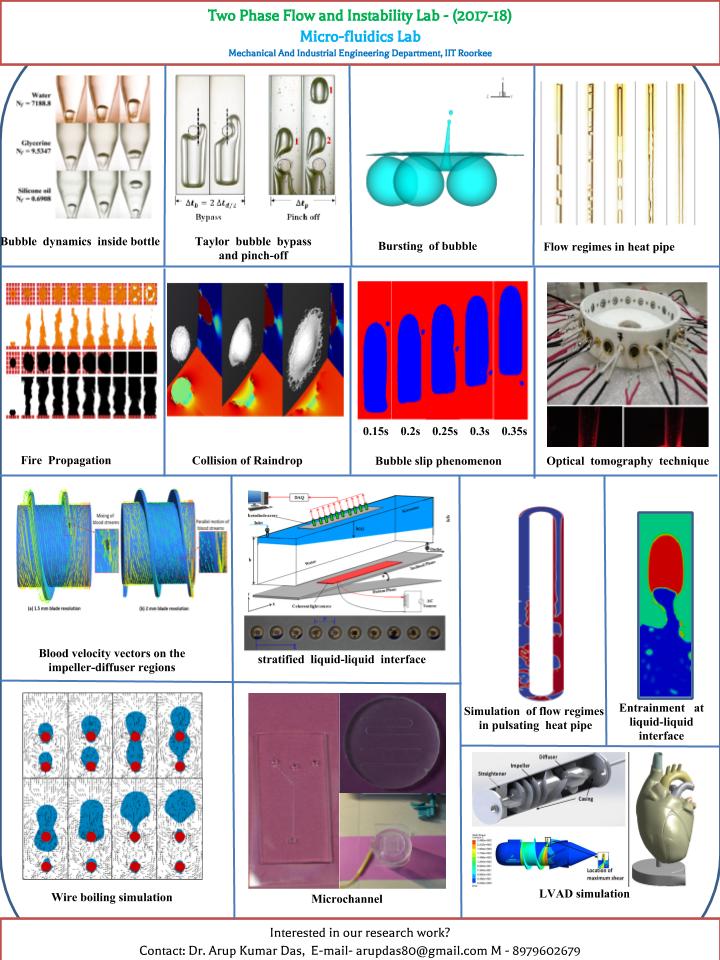

Development of Closed loop pulsating heat pipes for application at elevated evaporator temperaturePulsating heat pipe (PHP) is a closed two-phase heat transfer device in which heat is transported from the evaporator section to the condenser section due to oscillating motion of the working fluid. Proper designing and better thermal performance of a PHP require considerations of the physical phenomena occurring inside it. These phenomena are primarily controlled by thermo-physical properties of the working fluid, the geometrical parameters of the PHP and the operational parameters or constraints to the system. Though simple in construction, the complicated thermo-fluidic physics of the PHPs and the high heat transfer rate has motivated the candidate to implement it for high temperature applications keeping the emphasis focused on nuclear power plants. In this study, the main aim is to increase the operational temperature range of the PHP. In this regard, suitable heat transfer fluids (KoolGard, Olive oil, Therminol-66 and Dowtherm-A) are considered to investigate the thermo-fluidic behaviour of the device. Initially, experiments are performed to study the behaviour of the fluid inside the PHP made of quartz tube. Complementary experiments are performed in copper tube made metallic loop for temperature measurements in PHP. Thereafter, the selected fluids are analysed over the important dimensionless numbers affecting the thermal performance of the PHP. Phenomenal difference in start-up, operational behaviour and flow regimes is observed for different fluids, which could be attributed to the difference in thermo-physical properties of fluids and their capability for transferring heat. Comparing rigorous experimental results for different fluids, Dowtherm A is selected as a possible option for high temperature applications and investigated for the later part of the work. Next, detailed experiments are planned to study the flow behavior and heat transfer characteristic of water (as benchmark fluid) and Dowtherm-A in a three-turn CLPHP. Variation of important operational parameters, mainly heat input, filling ratio and inclination angle are considered and their effect on the thermal performance of the device is investigated. Effect of inclination is studied for two mutually perpendicular axes of rotation. Investigation reveals the characteristic behavior of the fluid and establishes operational domain in terms of the controlling parameters. Successful start-up and operation at high temperature is achieved using Dowtherm-A. It has been also observed through experiment that the number of turns (N) is one of the primary parameters affecting the performance of the PHP. A low value of N puts limit over the performance of the PHP at different orientations. However, higher value of N relaxes this limit imposed by the gravitational force and scales up the heat transport capacity of the device, yet very large N leads to a detrimental effect in transfer of heat flux. Thus, a critical N exists which is observed to be strongly dependent on the working fluid. Therefore, after establishing successful operation of the PHP with working fluid Dowtherm-A in three-turn PHP, experiments are conducted in 14 and 30-turn PHPs for high temperature industrial applications. Parametric variation similar to that performed for three-turn PHP is considered. Using experimental results for various heat input and filling ratio, in a similar path as for three-turn PHP, operational limits and optimum value for performance have been proposed. For inclination angle, improvement in performance is observed with the increase in N. Further, with the 30-turn PHP, performance, independent of inclination, is achieved at high heat input. We are delighted to share that All India Institute of Medical Sciences AIIMS Rishikesh doctors have confirmed the reliability and effectiveness of the completely indigenous low-cost portable ventilator named as ‘Prana-Vayu developed by IIT Roorkee after testing it at the hospital's Advanced Simulation Lab. Prana-Vayu is equipped with feedback control and real-time respiratory monitoring with wired and/or remote interface & was developed by IITRoorkee in collaboration with AIIMS Rishikesh. The design has been under continuous improvement in the last two months since the first version of the prototype was developed. The bill of materials cost of the Prana-Vayu ventilator is nearly one-fifth of the cheapest commercially available ventilator. This ventilator technology can facilitate increase in the number of ventilator equipped hospital beds after the #COVID19 pandemic. Join me in congratulating the entire team for their dedication and tireless efforts. Kudos to Team Prana-Vayu.

|

Dr. Arup Kumar DasHere you will get the latest updates of the research work. Archives

November 2021

Categories |

RSS Feed

RSS Feed