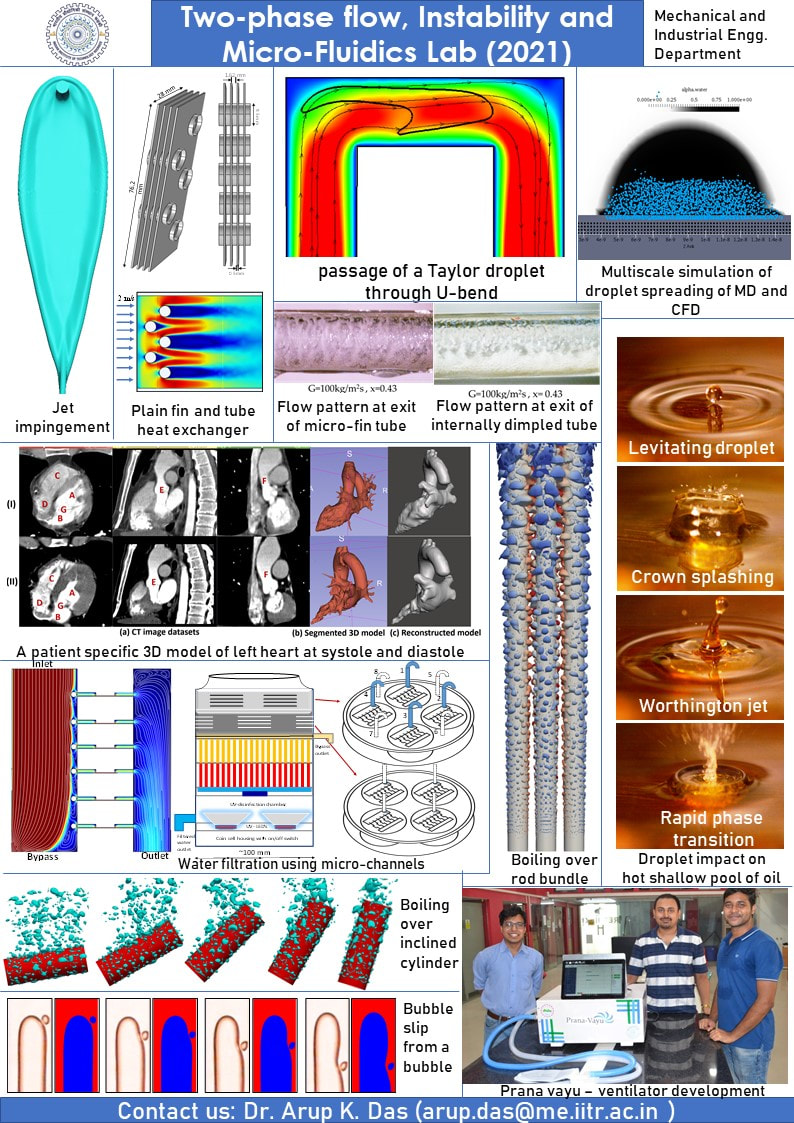

Research Work Highlights - Updated June 2021

Saliva Test kit for Human Fatigue Assessment |

|

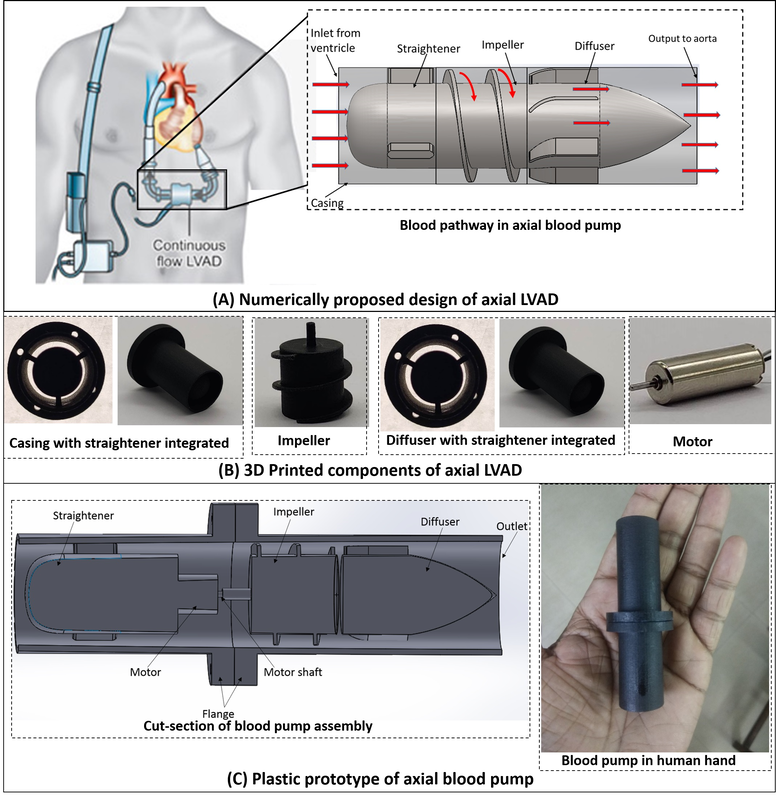

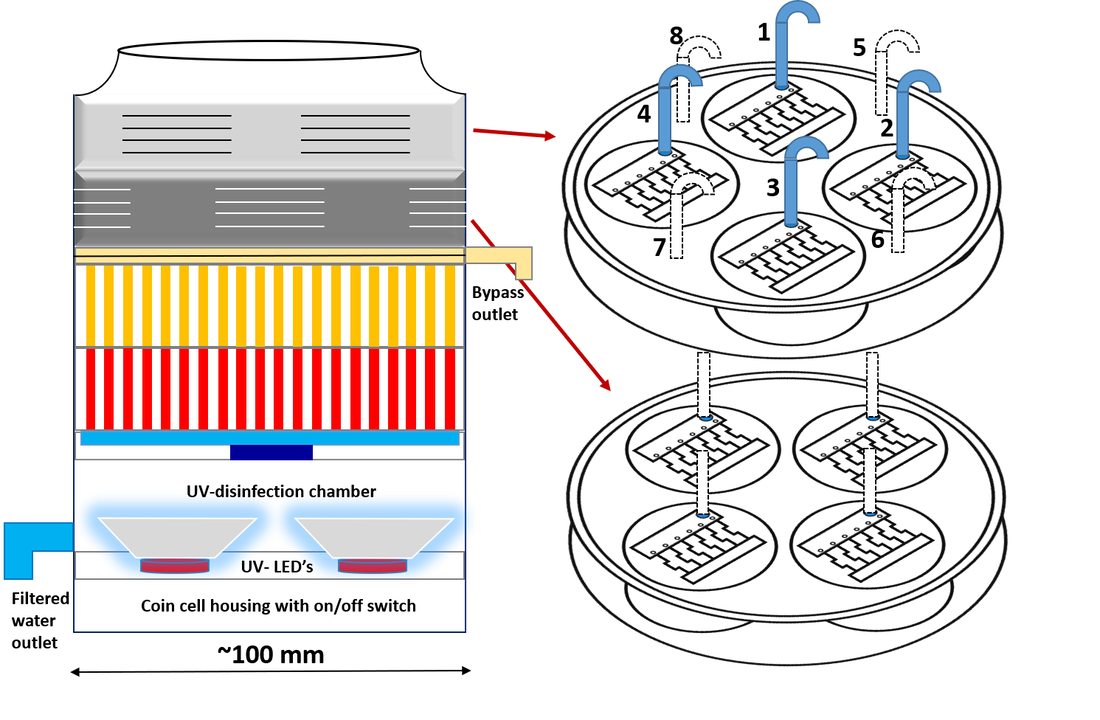

Axial Blood Pump Fabrication

- Different individual components are developed using HP Multi Jet Fusion printer. Nylon PA 12 material is used for 3D printing.

- Casing with the integrated straightener is having a 10 mm long cavity (diameter 7 mm) at the back end of the straightener to place the DC motor. After placing the DC motor, it’s shaft is connected to the corresponding hole provided at the front end of the impeller. Both parts of the casing are joined together through the flange coupling mechanism.

- Experimentation on axial blood pump has been carried out by using water as the working fluid.

- A measuring type of container has been utilized to measure the outlet flow rate of the pump.

- A numerical simulation has also been carried out at similar operating conditions and the same working fluid.

Flow Pattern of Refrigerant at the Exit of Internally Micro-dimpled Tube |

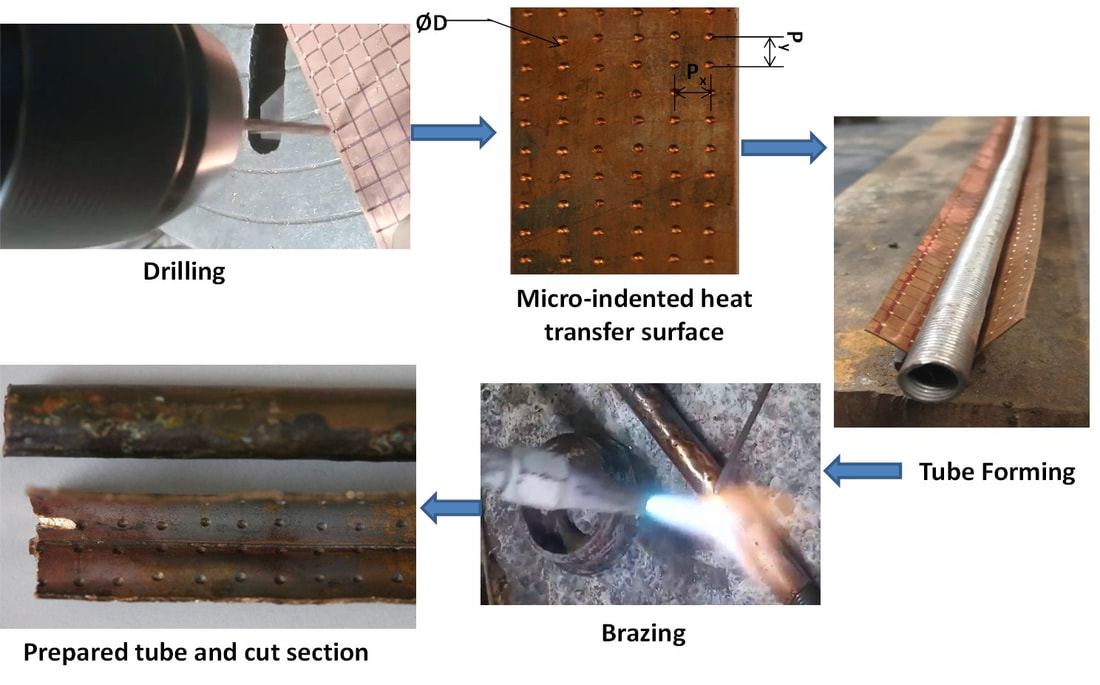

Development of new tube with micro-indentations at internal surface

|

In above video, Flow Pattern of Refrigerant at the Exit of Internally Micro-dimpled Tube is shown. The image shows manufacturing steps for development of a new tube with micro indentations on internal surface of tube.

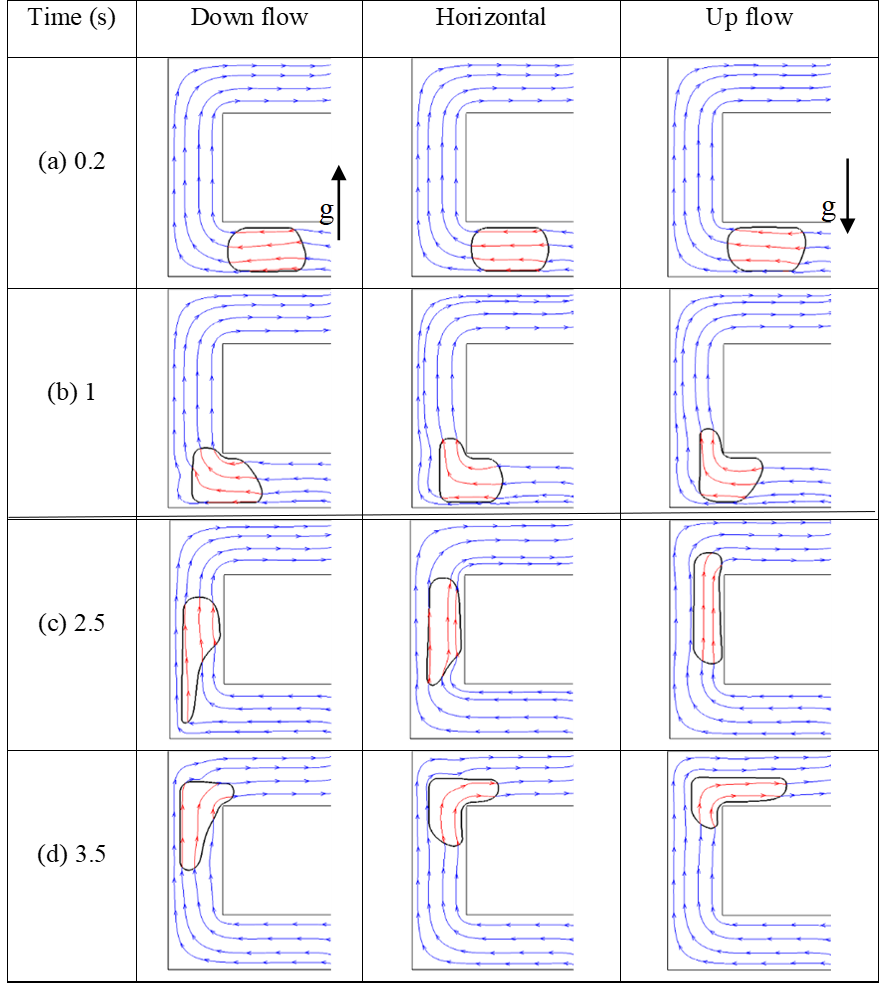

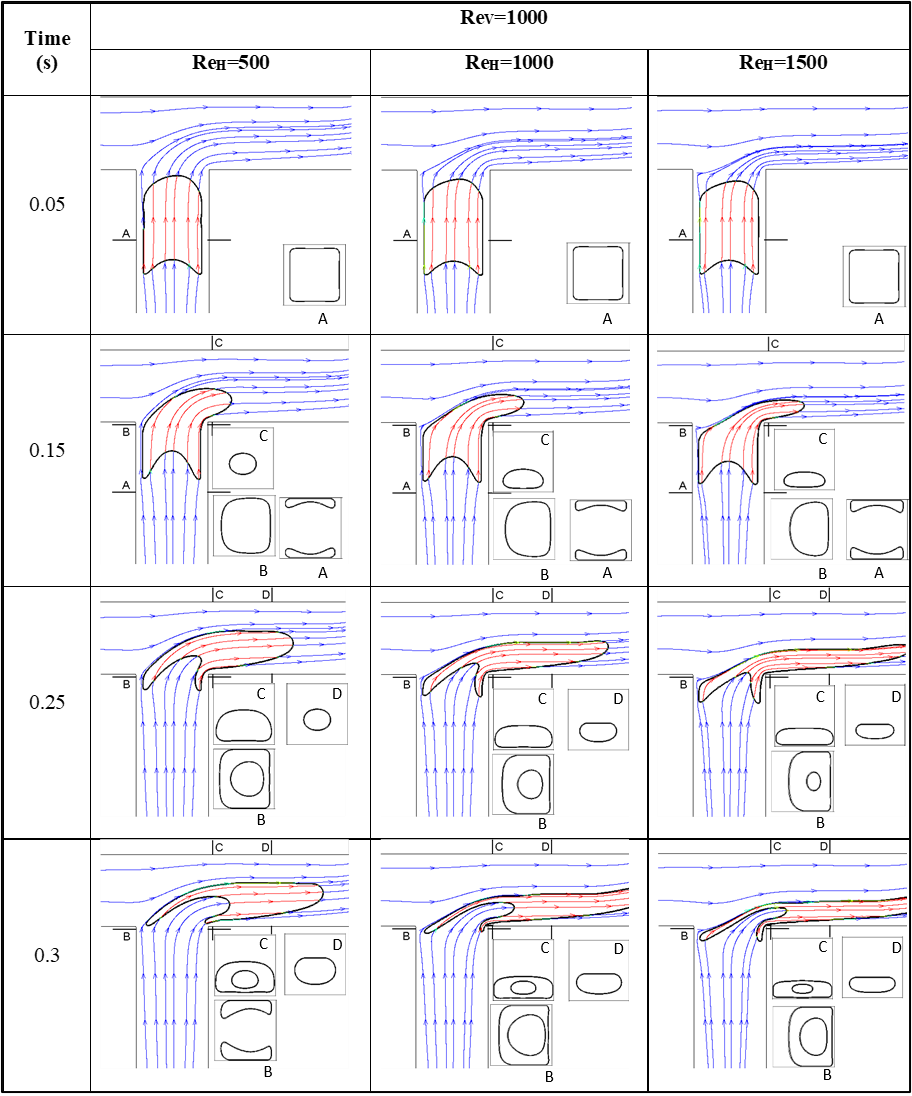

U Bend:

- Droplet head becomes sharper in the up flow compared to horizontal and down flow.

- Tail end of the droplet elongates in the down flow compared to the horizontal and up flow.

- Droplet head becomes sharper in the U bend compared to Z bend.

- Tail end of the droplet elongates in the Z bend in compared to U bend.

- As the ReH increases, head of the droplet is becoming more sharp and also getting closer to the bottom wall of the horizontal section.

- As the ReH increases, tail end of the droplet become more elongated and thin.

- Due to horizontal velocity, droplet is asymmetric in vertical limb (B), in horizontal limb (C & D).

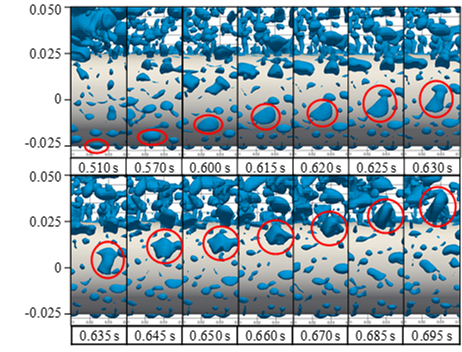

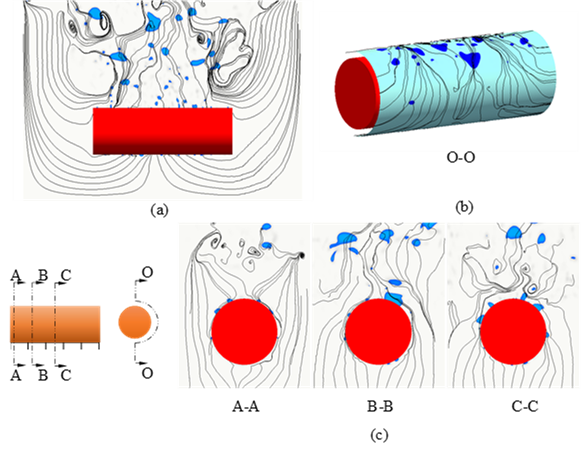

Different stages of a bubble growth, sliding, merging and departure over the cylinder while sliding over the heated cylinder in case of boiling around horizontal cylinder

Phase contour of Inner gas of bubble bursting at free surface; High pressure inner gas initially releases at much faster rate than the rate with which cavity retracted. Due to high relative velocity at the interface of gas phases (inner and outside), interfacial instability tried to engulf the outside gas which is clearly observed in subsequent sequence. Mushroom shaped head structure which is growing further as time progress. Tiny bubble entrapment after collapse of ripple at bottom most point.